Projects

Primary tabs

Acoustics and Fluid Mechanics

As the field of hypersonic vehicle design develops, having shear stress data can aid in the minimization of

drag source effects and verify results from computational fluid dynamics simulations. Transducer size,

placement, and narrow bandwidth currently limit accurate shear stress measurements due to the small

length and time scales seen in turbulent fluid motion and the issue of flow disruption. Shock wave and

boundary layer effects also produce large thermal loads in hypersonic flows. The proposed research plan

includes the design, optimization, fabrication, and testing of a flat-packed, sapphire MEMS optical shear

stress sensor. The material selection will ensure sensor functionality up to 1000°C, while microfabrication

techniques will extend the bandwidth to capture sub-mm wavelength phenomena. After an optimized

sensor design is selected and produced, it will be packaged and calibrated in static and dynamic

environments, making it viable for real-world hypersonic applications.

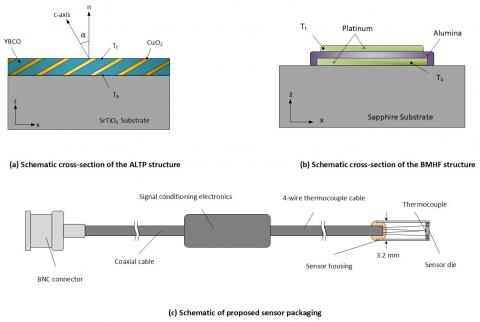

Understanding the character and dynamics of hypersonic boundary layers poses a considerable challenge to the design of hypersonic vehicles. Specifically, being able to predict the location of laminar-to-turbulent transition is of critical concern as it affects heating rates, aerodynamic loading, and skin-friction drag, therefore impacting the design of the thermal protection system and thus the overall weight and performance of the vehicle. In addition, complex turbulent flow dynamics play a significant role in a variety of vehicle flow situations including separated flows, control surface flows, and shock-wave/boundary layer interactions. Heat-flux sensors capable of measuring large thermal loads and their fluctuations are critical to capturing accurate estimates of the transition location, but current technology suffers from substantial calibration-driven measurement uncertainty and insufficient bandwidth. The proposed project aims to satisfy the existing demand for transition prediction technology via the development of an ultra-miniature, high-bandwidth Atomic Layer Thermopile (ALTP) while developing NIST-tracable calibration methods. For risk mitigation, a second device, a bimetallic heat flux sensor (BMHF) utilizing thin-film resistors surrounding a dielectric layer, will be fabricated to ensure smaller sensor packaging and increased operational temperature range. This work is expected to yield commercial, instrumentation-grade, miniature sensors that directly measure instantaneous, mean and fluctuating heat flux for time-resolved, quantitative measurements of heat flux in hypersonic flows.

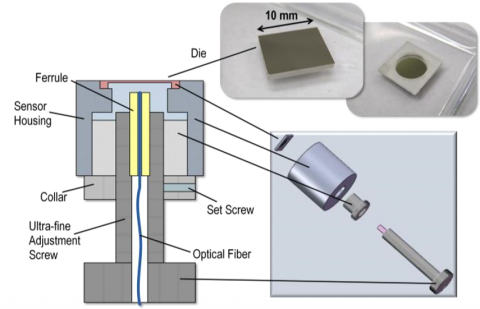

The goal of this research is to develop a MEMS-based Five-hole Probe(5HP) that is able to measure the localized velocity vector (both the velocity magnitude and direction) and the static and dynamic pressure, in steady and/or unsteady flow fields. Five optical pressure sensors located on the hemisphere tip of the 5HP provide all information that is needed to resolve the flow. This 5HP is expected to be able to provide high spatial resolution, high frequency response and is compatible with elevated temperature environments. A primary focus of this research is on the microfabrication and micromachining of a die that incorporates five optical transducers and its successive packaging process. The completed sensors will be tested in flow cells and wind tunnels at UF for the final calibration.

This Center of Excellence (COE) will conduct fundamental research that transforms the way in which conventional distributed sensing, state estimation, morphing structures, and control are applied to high-speed aerospace systems. Our team will address the limitation of conventional feedback loops using novel sensing motifs and inherent coupling to adaptive structures to create an agile and robust aerospace system with integrated sense, assess, and respond functionality. To achieve this goal, we propose an inter-disciplinary approach that leverages diverse methodologies and team member expertise in information theory, physics-based models, reservoir computing, sensors for high-speed environments, morphing structures, control, and experimental aerodynamics to meet the goals of an integrated sense, assess, and respond framework. This foundational research will explore and develop advanced information processing methods that can rapidly convert sensor data into actionable information through a physical interpretation of aerodynamic structural dynamic responses in real-time. Relationships between information theory and physical models will advance beyond conventional statistical mechanics, thermodynamics, and dynamical systems and will be tested experimentally to demonstrate how adaptive aerospace structures extract data, convert it into information, and formulate knowledge about complex aerospace structures operating in high-speed environments. This information will be used to define morphing materials requirements and help guide systems integration for nonlinear control strategies. We will apply tools from information theory, network science, reduced-order multi-physics fluid-structure modeling, physical reservoir computing, advanced sensing, experimental aerodynamics, and control to create an integrated sense, assess, and respond aerodynamic system. This research will be executed in close collaboration with AFRL-RW, RX, and RQ through workforce development and joint projects to facilitate transition of fundamental research to the next generation warfighter.

Visit this link for more information.

*Picture from the UF engineering news webpage

This project focuses on the development of a non-intrusive, direct, time-resolved wall shear stress sensor system for low-speed applications. The goals of the project include the fabrication and packaging of a 2-D wall-shear stress sensor with backside wire bond contacts to ensure hydraulic smoothness in flow environments. A differential capacitance transduction scheme is utilized with interdigitated comb fingers on each side of a suspended floating element, allowing for measurements to be made in both the positive and negative x- and y-directions. A synchronous modulation-demodulation circuit is employed to simultaneously capture both mean and fluctuating shear content. Both AC and DC calibrations are performed to determine sensor sensitivity in both directions of transduction. This is the most successful effort of shear sensor development in published literature.

A diverse team led by three ECE Florida faculty members is set to receive funding from the Defense Advanced Research Projects Agency (DARPA) to design and fabricate dynamic pressure sensors capable of performing at temperatures upwards of 800 °C (1472 °F), over a factor of 6X higher than any integrated pressure sensor currently in use. The $6.6M project, funded as part of the DARPA High Operational Temperature Sensors (HOTS) program, seeks to enable all manners of electronics and sensors that would be integral to industrial, military, and space applications. The core team is comprised of Dr. Mark Sheplak (lead PI), Dr. Roozbeh Tabrizian, and Dr. Philip Feng.

Visit the link for more information.

*Picture from the ECE news page.

The primary objective of this research is to develop a high-bandwidth pressure sensor to provide benchmark, time-resolved, dynamic pressure data in high-temperature combustion environments. Specifically, these sensors will be designed to be embedded within a system and provide remote interrogation which will enable pressure to be measured in situ and on line under extreme conditions. Ultimately, this sensing technology will lead to better understanding and increased efficiency of complex power generation systems. In order to achieve this objective, research in sapphire laser micromachining and thermocompression bonding via spark plasma sintering technology will be conducted to enable fabrication of a fiber optic lever pressure sensor that uses a sapphire optical fiber for transduction of the pressure-induced diaphragm deflection. The proposed project will result in instrumentation-grade, high-temperature sensors that enable flush mounted measurements without sensor cooling. Furthermore, the use of optical techniques enables “passive” device operation, with electronics located remotely from the sensor. After fabrication and packaging, the pressure sensor will be rigorously characterized in acoustic plane wave tubes under both ambient and high-temperature conditions to determine its performance as a quantitative measurement device.

We are developing time-resolved dynamic pressure sensing technology for high-temperature (> 1000 °C) applications in the aerospace, energy, and automotive sectors and for chemical environment sensors for biotechnology companies.

Almost all of the existing pressure sensing systems are not capable of operation in environments in excess of 1000 °C. Those systems that can survive the extreme temperatures suffer from reduced performance and induced bias errors arising from temperature mitigation efforts. We will investigate wireless, electromagnetic wave-guide and sapphire-based fiber optical based transduction technology combined with laser micromachining of sapphire and platinum film deposition to dynamic pressure sensors capable of continuous operation at 1000 °C. These technologies eliminate the need for close proximity electronics and will be fabricated from high-temperature capable materials that possess nearly identical thermal coefficients of expansion to minimize thermal drift.

Electromagnetics and Photonics

As the field of hypersonic vehicle design develops, having shear stress data can aid in the minimization of

drag source effects and verify results from computational fluid dynamics simulations. Transducer size,

placement, and narrow bandwidth currently limit accurate shear stress measurements due to the small

length and time scales seen in turbulent fluid motion and the issue of flow disruption. Shock wave and

boundary layer effects also produce large thermal loads in hypersonic flows. The proposed research plan

includes the design, optimization, fabrication, and testing of a flat-packed, sapphire MEMS optical shear

stress sensor. The material selection will ensure sensor functionality up to 1000°C, while microfabrication

techniques will extend the bandwidth to capture sub-mm wavelength phenomena. After an optimized

sensor design is selected and produced, it will be packaged and calibrated in static and dynamic

environments, making it viable for real-world hypersonic applications.

The goal of this research is to develop a MEMS-based Five-hole Probe(5HP) that is able to measure the localized velocity vector (both the velocity magnitude and direction) and the static and dynamic pressure, in steady and/or unsteady flow fields. Five optical pressure sensors located on the hemisphere tip of the 5HP provide all information that is needed to resolve the flow. This 5HP is expected to be able to provide high spatial resolution, high frequency response and is compatible with elevated temperature environments. A primary focus of this research is on the microfabrication and micromachining of a die that incorporates five optical transducers and its successive packaging process. The completed sensors will be tested in flow cells and wind tunnels at UF for the final calibration.

The primary objective of this research is to develop a high-bandwidth pressure sensor to provide benchmark, time-resolved, dynamic pressure data in high-temperature combustion environments. Specifically, these sensors will be designed to be embedded within a system and provide remote interrogation which will enable pressure to be measured in situ and on line under extreme conditions. Ultimately, this sensing technology will lead to better understanding and increased efficiency of complex power generation systems. In order to achieve this objective, research in sapphire laser micromachining and thermocompression bonding via spark plasma sintering technology will be conducted to enable fabrication of a fiber optic lever pressure sensor that uses a sapphire optical fiber for transduction of the pressure-induced diaphragm deflection. The proposed project will result in instrumentation-grade, high-temperature sensors that enable flush mounted measurements without sensor cooling. Furthermore, the use of optical techniques enables “passive” device operation, with electronics located remotely from the sensor. After fabrication and packaging, the pressure sensor will be rigorously characterized in acoustic plane wave tubes under both ambient and high-temperature conditions to determine its performance as a quantitative measurement device.

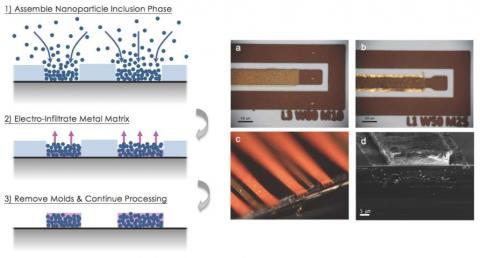

As predicted by Moore's "law", the past few decades have seen massive reductions in the size of integrated circuits, enabling the portable, handheld devices now in everyday use. However, the components that power these devices have not experienced a similar size reduction. For example, the power adapter of a laptop computer is only modestly smaller than that two decades ago, and the printed circuit board inside a smart phone must dedicate between 20% and 40% of the board area for power conversion and management. To date, efforts towards miniaturization have been limited by both materials and manufacturing challenges. To address this gap, this research will study nanomanufacturing processes to facilitate the scalable synthesis of high quality magnetic nanoparticles and nanocomposite core materials and the fabrication of compact power inductors and transformers through assembly of these nanomaterials in a manner that is compatible with current manufacturing processes, such as silicon wafer or printed circuit board fabrication. This compatibility will enable fully integrated and compact system-on-chip or system-in-package power solutions. This research will be accomplished by fostering collaboration among disciplines including materials science, chemical engineering and electrical engineering. It will foster diversity in the profession by involving high school and undergraduate students in research activities and by broadening participation through the inclusion and engagement of women and underrepresented groups.

The overarching goal of this Scalable Nanomanufacutring project is to study synthetic and nanomanufacturing processes that overcome existing integration challenges while affording breakthrough, high-frequency magnetic performance. An aim is to research materials that exhibit high magnetic saturation and low loss. This will be accomplished by leveraging the unique properties of magnetic materials at the nanoscale through a combination of nanomanufacturing approaches spanning bottom-up synthesis to directed assembly and nanocomposite formation. The specific objectives are to: (i) scale-up synthesis of high quality magnetic nanoparticles via thermal decomposition routes by elucidating the underlying correlations between synthesis parameters and nanoparticle properties, leveraging recent developments in the reproducible synthesis of near defect-free nanocrystals with magnetic properties approaching those of the bulk; (ii) study methods for large-scale directed assembly of magnetic nanoparticles via dielectrophoresis into compact power inductors/transformers; and (iii) demonstrate the formation of bi-phasic nanocomposite cores through large-scale electro-infiltration of an additional ferromagnetic material. An expected outcome of this project is to demonstrate scalability through the full-wafer batch-fabrication of microinductor devices using the developed methods on a silicon wafer. From a commercial standpoint, nanomanufacturing technologies providing process-integrable, high-performance magnetic components for power application have the potential to impact a nearly $12B/year market.

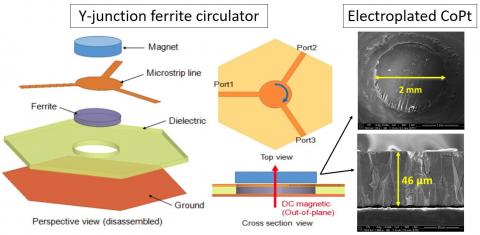

This project is under DARPA's Magnetic Miniaturized and Monolithically Integrated Components (M3IC) program in the DARPA Microsystems Technology Office.

The objective of this effort is to develop thick-film magnetic materials that can be fabricated on semiconductor integrated circuits to enable highly miniaturized microwave components such as circulators and isolators operating in the 10 to 110 GHz frequency regime. These nonlinear, non-reciprocal components are critical for next generation radios, radar, and sensing systems for defense, consumer, automotive, and healthcare applications.

Specific efforts include: (1) self-biased microwave magnetic thick-films on semiconductor substrates, (2) integration of permanent magnet bias magnets on semiconductor substrates, and (3) integrated microwave magnetic components on semiconductor substrates.

This project studies on wave propagation in waveguide with periodical boundaries, in such a case, a new kind of resonance occurs. This new kind of resonance is very different from the traditional Bragg resonance.

In Non-Bragg resonance, the resonance frequency and bandwidth strongly depends on the geometric configuration of the waveguide, and, the resonance is tunable. Theoretical and experimental results show good agreements.

The goal of this project is to develop micro-LiDAR with small size and low power consumption for flapping-wing micro-aerial vehicles. The micro-LiDAR will be based on electrothermally-actuated scanning micromirrors.

We are developing time-resolved dynamic pressure sensing technology for high-temperature (> 1000 °C) applications in the aerospace, energy, and automotive sectors and for chemical environment sensors for biotechnology companies.

Almost all of the existing pressure sensing systems are not capable of operation in environments in excess of 1000 °C. Those systems that can survive the extreme temperatures suffer from reduced performance and induced bias errors arising from temperature mitigation efforts. We will investigate wireless, electromagnetic wave-guide and sapphire-based fiber optical based transduction technology combined with laser micromachining of sapphire and platinum film deposition to dynamic pressure sensors capable of continuous operation at 1000 °C. These technologies eliminate the need for close proximity electronics and will be fabricated from high-temperature capable materials that possess nearly identical thermal coefficients of expansion to minimize thermal drift.

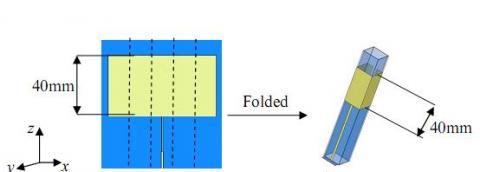

A Folded Patch antenna is investigated both theoretically and experimentally. The proposed antenna is very compact, and can be matched to desired impedance without any external matching circuitry. The proposed antenna also offers EM shielding to the internal PCB. Further, omni directional radiation pattern is obtained which is not feasible on traditional patch antennas.

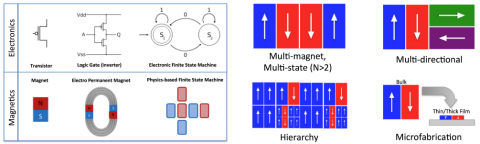

This collaborative research project will create a practical control scheme for large swarms of microrobots. These robots are typically no more than a few millimeters in length, and rely on an external power source and control signal. Currently, it is possible to steer the swarm as a whole to a single destination (or perhaps, to a desired average location). However, realizing the full potential benefits of microrobot swarms will require the ability to simultaneously send independent commands, either to individual robots or to small subgroups. Device designs have previously been explored that respond to different command amplitudes, however this approach quickly becomes impractical as the number of independently addressable robots grows. This scalability problem can be overcome using serial addressing schemes. Here, there are only a few distinct values for the control signal. Each independently addressable subset of robots is associated with a unique sequence of signal values, and will change its behavior only if the control signal contains that specific sequence. This project considers two fundamental issues that arise in implementing such a scheme. First is the need for on-board computation and memory allowing the robots to recognize the unique sequence and to change the robots state based on the detection of such sequence. Second is the need for a propulsive mechanism that couples to the robot state to allow differential guidance towards a target configuration. This project will advance two innovative engineering platforms that meet both needs. The first is electrostatically actuated, operates on a planar substrate, and is suitable for structured tasks such as microassembly. The second is magnetically actuated, operates in a liquid volume, and is suitable for biomedical applications such as drug delivery. The technical aspects of the project are complimented by outreach activities, including an annual microrobotics mobility competition to be held at the IEEE International Conference on Robotics and Automation -- a premier robotics conference for academia and industry. The results from this project will enhance the national health, by enabling new diagnostic and therapeutic uses for microrobot swarms. They will also promote the national prosperity, by enabling new classes of microassembly robots.

This project aims to develop a practical control scheme to simultaneously control large numbers of microrobots. This will be achieved by using microelectromechanical systems (MEMS) to electromechanically and magnetically decode a sequence embedded in the single global control signal, and couple the reconfiguration of such sequence to the modification of the individual microrobot trajectories. This on-board sequence decoding will be accomplished through sets of on-board physics-based finite state machines (PFSM) that can accept a control sequence embedded in the control signal and change the behavior of the microrobots accordingly. The project will use both electrostatic and magnetic approaches to implement PFSMs, and to couple their "accept" state to the propulsion mechanism to modulate individual trajectories. Sets of stress-engineered electrostatic switches, which will latch in response to a pre-programmed control voltage sequence, will be used to implement PFSM on the electrostatic platform. Electro-permanent magnetic circuits, which change their magnetic moment in response to a sequence of global magnetic field, will be used to implement PFSM on the magnetic platform. The project will develop the theory for PFSM-based multi-microrobot control, construct both electrostatic and magnetic microrobotic PFSM platforms, and validate the concept by implementing the PFSM-based control on swarms of electrostatically and magnetically powered microrobots. The developed theory and approach will pave way for control of large microrobot swarms for numerous biomedical and microassembly applications.

We are developing ultra-compact antennas, where the antenna size is much smaller than the electromagnetic wavelength.

Pervasive wireless connectivity is a must for today’s interconnected world. Many MHz-GHz communication systems require antennas with physical sizes that can be much larger than the entire size of the system. It is difficult to achieve good antenna performance if the size of the antenna is less than 1/10ththe electromagnetic wavelength (e.g. minimum of 3 cm at 1 GHz)

Our breakthrough approach is radically different than traditional conductive-wire type antennas. Rather than relying on moving charge to enact antenna functionality, we make use of functional materials. Specifically magnetoelectric composite nanowires (strain-coupled piezoelectric + magnetostrictive materials) respond to an electromagnetic field by directly producing a voltage. This is material effect, rather than a purely electromagnetic effect. Additionally, the antenna performance can be dramatically enhanced by tuning the mechanical/acoustic resonance of the device to the target frequency band. The ability to make ultra-compact antennas, and potentially on-chip with integrated electronics could drastically reduce the size, weight, and power (SWAP) of multi-functional systems.

Materials, Manufacturing, and Modeling

As the field of hypersonic vehicle design develops, having shear stress data can aid in the minimization of

drag source effects and verify results from computational fluid dynamics simulations. Transducer size,

placement, and narrow bandwidth currently limit accurate shear stress measurements due to the small

length and time scales seen in turbulent fluid motion and the issue of flow disruption. Shock wave and

boundary layer effects also produce large thermal loads in hypersonic flows. The proposed research plan

includes the design, optimization, fabrication, and testing of a flat-packed, sapphire MEMS optical shear

stress sensor. The material selection will ensure sensor functionality up to 1000°C, while microfabrication

techniques will extend the bandwidth to capture sub-mm wavelength phenomena. After an optimized

sensor design is selected and produced, it will be packaged and calibrated in static and dynamic

environments, making it viable for real-world hypersonic applications.

Understanding the character and dynamics of hypersonic boundary layers poses a considerable challenge to the design of hypersonic vehicles. Specifically, being able to predict the location of laminar-to-turbulent transition is of critical concern as it affects heating rates, aerodynamic loading, and skin-friction drag, therefore impacting the design of the thermal protection system and thus the overall weight and performance of the vehicle. In addition, complex turbulent flow dynamics play a significant role in a variety of vehicle flow situations including separated flows, control surface flows, and shock-wave/boundary layer interactions. Heat-flux sensors capable of measuring large thermal loads and their fluctuations are critical to capturing accurate estimates of the transition location, but current technology suffers from substantial calibration-driven measurement uncertainty and insufficient bandwidth. The proposed project aims to satisfy the existing demand for transition prediction technology via the development of an ultra-miniature, high-bandwidth Atomic Layer Thermopile (ALTP) while developing NIST-tracable calibration methods. For risk mitigation, a second device, a bimetallic heat flux sensor (BMHF) utilizing thin-film resistors surrounding a dielectric layer, will be fabricated to ensure smaller sensor packaging and increased operational temperature range. This work is expected to yield commercial, instrumentation-grade, miniature sensors that directly measure instantaneous, mean and fluctuating heat flux for time-resolved, quantitative measurements of heat flux in hypersonic flows.

The goal of this research is to develop a MEMS-based Five-hole Probe(5HP) that is able to measure the localized velocity vector (both the velocity magnitude and direction) and the static and dynamic pressure, in steady and/or unsteady flow fields. Five optical pressure sensors located on the hemisphere tip of the 5HP provide all information that is needed to resolve the flow. This 5HP is expected to be able to provide high spatial resolution, high frequency response and is compatible with elevated temperature environments. A primary focus of this research is on the microfabrication and micromachining of a die that incorporates five optical transducers and its successive packaging process. The completed sensors will be tested in flow cells and wind tunnels at UF for the final calibration.

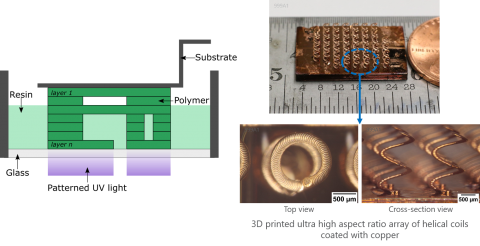

The goal of this project is to develop processes that will advance microfabrication technologies using stereolithography as the additive manufacturing (3D printing) method. This project focuses on fabrication of multifunctional devices that are both high resolution (tens of micrometers) and large area (tens of millimeters). The ability to fabricate functional microdevices using 3D printing can enable novel devices in the area of MEMs, sensors, actuators, microrobots, micro-optics, radio frequency, etc. Such devices have applications ranging from IoT, communication, healthcare, transportation, etc.

This project focuses on the development of a non-intrusive, direct, time-resolved wall shear stress sensor system for low-speed applications. The goals of the project include the fabrication and packaging of a 2-D wall-shear stress sensor with backside wire bond contacts to ensure hydraulic smoothness in flow environments. A differential capacitance transduction scheme is utilized with interdigitated comb fingers on each side of a suspended floating element, allowing for measurements to be made in both the positive and negative x- and y-directions. A synchronous modulation-demodulation circuit is employed to simultaneously capture both mean and fluctuating shear content. Both AC and DC calibrations are performed to determine sensor sensitivity in both directions of transduction. This is the most successful effort of shear sensor development in published literature.

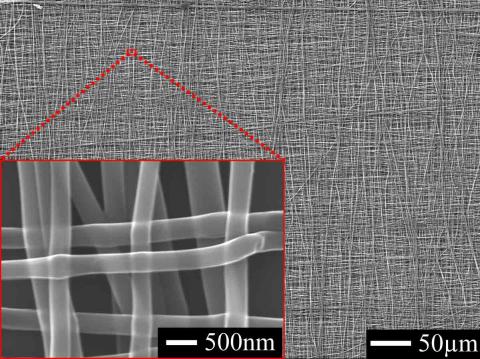

The Electrospinning and Stamp-thru-mold (ESTM) technique, an integrated fabrication process which incorporates the versatility of the electrospinning process for nanofiber fabrication with

the non-lithographic patterning ability of the stamp-thru-mold process is introduced. In-situ multilayer stacking of orthogonally aligned nanofibers, ultimately resulting in a nanoporous membrane, has been demonstrated using orthogonally placed collector electrode pairs and an alternating bias scheme. The pore size of the nanoporousmembrane can be controlled by the number of layers and the deposition time of each layer. Non-lithographic patterning of the fabricated nanoporousmembrane is then performed by mechanical shearing using a pair of pre-fabricated micromolds. This patterning process is contamination free compared to other photo lithographical patterning approaches. The ability to pattern on different substrates has been tested with and without oxygen plasma surface treatment. In vitro tests of ESTM poly-lactic-coglycolic acid (PLGA) nanofibers verify the biocompatibility of this process. Simulation by the COMSOL Multiphysics tool has been conducted for the analysis of electrospun nanofiber alignment.

The primary objective of this research is to develop a high-bandwidth pressure sensor to provide benchmark, time-resolved, dynamic pressure data in high-temperature combustion environments. Specifically, these sensors will be designed to be embedded within a system and provide remote interrogation which will enable pressure to be measured in situ and on line under extreme conditions. Ultimately, this sensing technology will lead to better understanding and increased efficiency of complex power generation systems. In order to achieve this objective, research in sapphire laser micromachining and thermocompression bonding via spark plasma sintering technology will be conducted to enable fabrication of a fiber optic lever pressure sensor that uses a sapphire optical fiber for transduction of the pressure-induced diaphragm deflection. The proposed project will result in instrumentation-grade, high-temperature sensors that enable flush mounted measurements without sensor cooling. Furthermore, the use of optical techniques enables “passive” device operation, with electronics located remotely from the sensor. After fabrication and packaging, the pressure sensor will be rigorously characterized in acoustic plane wave tubes under both ambient and high-temperature conditions to determine its performance as a quantitative measurement device.

The combined application of stress, temperature, and bias has the potential to enhance FRAM (ferroelectric random access memory) performance at the 130-nm technology node and possibly extend the technology to the 90-nm node and beyond. While temperature and bias have been traditionally used to pole ferroelectric thin-films, applied stress has also been shown to enhance ferroelectric properties. This can lead to an improved FRAM signal margin, which is a key metric for FRAM reliability and performance. We propose to comprehensively study the effects of stress, temperature, and bias on the ferroelectric properties of fully integrated thin-film PZT ferroelectric capacitors. These effects will be investigated experimentally. We will then develop SPICE simulation models and simulate the stress in ferroelectric films based on TI’s 130-nm process. Our goal is to gain a deep understanding of the underlying physics of stress effects at bias and temperature on ferroelectric capacitors, and use this knowledge to develop accurate models that can simulate these effects and be used in FRAM design. We will then recommend strain-engineering methods for enhancing FRAM performance at the 130-nm node and beyond.

Advancing FRAM technology beyond the 130-nm node can increase storage density and reduce cost, leading to new potential markets and applications. However, further scaling of ferroelectric PZT films can diminish FRAM performance. It has been suggested that scaling beyond the 130-nm technology node will require different FRAM structure and materials, which can lead to increased costs and development time. We propose that stress engineering may be a solution to enhance current FRAM technology and extend it to the 90-nm node and beyond.

As predicted by Moore's "law", the past few decades have seen massive reductions in the size of integrated circuits, enabling the portable, handheld devices now in everyday use. However, the components that power these devices have not experienced a similar size reduction. For example, the power adapter of a laptop computer is only modestly smaller than that two decades ago, and the printed circuit board inside a smart phone must dedicate between 20% and 40% of the board area for power conversion and management. To date, efforts towards miniaturization have been limited by both materials and manufacturing challenges. To address this gap, this research will study nanomanufacturing processes to facilitate the scalable synthesis of high quality magnetic nanoparticles and nanocomposite core materials and the fabrication of compact power inductors and transformers through assembly of these nanomaterials in a manner that is compatible with current manufacturing processes, such as silicon wafer or printed circuit board fabrication. This compatibility will enable fully integrated and compact system-on-chip or system-in-package power solutions. This research will be accomplished by fostering collaboration among disciplines including materials science, chemical engineering and electrical engineering. It will foster diversity in the profession by involving high school and undergraduate students in research activities and by broadening participation through the inclusion and engagement of women and underrepresented groups.

The overarching goal of this Scalable Nanomanufacutring project is to study synthetic and nanomanufacturing processes that overcome existing integration challenges while affording breakthrough, high-frequency magnetic performance. An aim is to research materials that exhibit high magnetic saturation and low loss. This will be accomplished by leveraging the unique properties of magnetic materials at the nanoscale through a combination of nanomanufacturing approaches spanning bottom-up synthesis to directed assembly and nanocomposite formation. The specific objectives are to: (i) scale-up synthesis of high quality magnetic nanoparticles via thermal decomposition routes by elucidating the underlying correlations between synthesis parameters and nanoparticle properties, leveraging recent developments in the reproducible synthesis of near defect-free nanocrystals with magnetic properties approaching those of the bulk; (ii) study methods for large-scale directed assembly of magnetic nanoparticles via dielectrophoresis into compact power inductors/transformers; and (iii) demonstrate the formation of bi-phasic nanocomposite cores through large-scale electro-infiltration of an additional ferromagnetic material. An expected outcome of this project is to demonstrate scalability through the full-wafer batch-fabrication of microinductor devices using the developed methods on a silicon wafer. From a commercial standpoint, nanomanufacturing technologies providing process-integrable, high-performance magnetic components for power application have the potential to impact a nearly $12B/year market.

This project is under DARPA's Magnetic Miniaturized and Monolithically Integrated Components (M3IC) program in the DARPA Microsystems Technology Office.

The objective of this effort is to develop thick-film magnetic materials that can be fabricated on semiconductor integrated circuits to enable highly miniaturized microwave components such as circulators and isolators operating in the 10 to 110 GHz frequency regime. These nonlinear, non-reciprocal components are critical for next generation radios, radar, and sensing systems for defense, consumer, automotive, and healthcare applications.

Specific efforts include: (1) self-biased microwave magnetic thick-films on semiconductor substrates, (2) integration of permanent magnet bias magnets on semiconductor substrates, and (3) integrated microwave magnetic components on semiconductor substrates.

We are developing time-resolved dynamic pressure sensing technology for high-temperature (> 1000 °C) applications in the aerospace, energy, and automotive sectors and for chemical environment sensors for biotechnology companies.

Almost all of the existing pressure sensing systems are not capable of operation in environments in excess of 1000 °C. Those systems that can survive the extreme temperatures suffer from reduced performance and induced bias errors arising from temperature mitigation efforts. We will investigate wireless, electromagnetic wave-guide and sapphire-based fiber optical based transduction technology combined with laser micromachining of sapphire and platinum film deposition to dynamic pressure sensors capable of continuous operation at 1000 °C. These technologies eliminate the need for close proximity electronics and will be fabricated from high-temperature capable materials that possess nearly identical thermal coefficients of expansion to minimize thermal drift.

The aim of this project is to utilize the controllable nature of Graphene Oxide as an ultrathin separation membrane in biological applications, specifically targetting removal of uremic toxins.

This collaborative research project will create a practical control scheme for large swarms of microrobots. These robots are typically no more than a few millimeters in length, and rely on an external power source and control signal. Currently, it is possible to steer the swarm as a whole to a single destination (or perhaps, to a desired average location). However, realizing the full potential benefits of microrobot swarms will require the ability to simultaneously send independent commands, either to individual robots or to small subgroups. Device designs have previously been explored that respond to different command amplitudes, however this approach quickly becomes impractical as the number of independently addressable robots grows. This scalability problem can be overcome using serial addressing schemes. Here, there are only a few distinct values for the control signal. Each independently addressable subset of robots is associated with a unique sequence of signal values, and will change its behavior only if the control signal contains that specific sequence. This project considers two fundamental issues that arise in implementing such a scheme. First is the need for on-board computation and memory allowing the robots to recognize the unique sequence and to change the robots state based on the detection of such sequence. Second is the need for a propulsive mechanism that couples to the robot state to allow differential guidance towards a target configuration. This project will advance two innovative engineering platforms that meet both needs. The first is electrostatically actuated, operates on a planar substrate, and is suitable for structured tasks such as microassembly. The second is magnetically actuated, operates in a liquid volume, and is suitable for biomedical applications such as drug delivery. The technical aspects of the project are complimented by outreach activities, including an annual microrobotics mobility competition to be held at the IEEE International Conference on Robotics and Automation -- a premier robotics conference for academia and industry. The results from this project will enhance the national health, by enabling new diagnostic and therapeutic uses for microrobot swarms. They will also promote the national prosperity, by enabling new classes of microassembly robots.

This project aims to develop a practical control scheme to simultaneously control large numbers of microrobots. This will be achieved by using microelectromechanical systems (MEMS) to electromechanically and magnetically decode a sequence embedded in the single global control signal, and couple the reconfiguration of such sequence to the modification of the individual microrobot trajectories. This on-board sequence decoding will be accomplished through sets of on-board physics-based finite state machines (PFSM) that can accept a control sequence embedded in the control signal and change the behavior of the microrobots accordingly. The project will use both electrostatic and magnetic approaches to implement PFSMs, and to couple their "accept" state to the propulsion mechanism to modulate individual trajectories. Sets of stress-engineered electrostatic switches, which will latch in response to a pre-programmed control voltage sequence, will be used to implement PFSM on the electrostatic platform. Electro-permanent magnetic circuits, which change their magnetic moment in response to a sequence of global magnetic field, will be used to implement PFSM on the magnetic platform. The project will develop the theory for PFSM-based multi-microrobot control, construct both electrostatic and magnetic microrobotic PFSM platforms, and validate the concept by implementing the PFSM-based control on swarms of electrostatically and magnetically powered microrobots. The developed theory and approach will pave way for control of large microrobot swarms for numerous biomedical and microassembly applications.

Spatially controlled electrospun solid gradient nanofibers for guided spiral ganglion neuron culture

The direction of cell growth is associated with chemical, structural and/or mechanical properties of the substrate. Structurally, electrospun nanofibers provide a suitable environment for cell attachment and proliferation due to their similar physical dimension to that of the extracellular matrix. Furthermore, by modulating the topographical features of nanofibers, which include fiber diameter and orientation, cell growth and its related functions can be modified. Here, we demonstrate a solid gradient scaffold for directional growth of spiral ganglion neurons (SGNs). Spatial nanofiber alignment is controlled using a custom directional electrospinning setup. The electric field to spatially control the confinement of nanofibers was simulated with COMSOL Multiphysics simulation tool and experimentally verified. To promote neurite outgrowth and impart directionality to SGN cells, a spatial gradient of neurotrophin (NT) is introduced. By sequentially electrospinning solutions of increasing concentrations of NT in the biodegradable polymer and collecting sections of these aligned fibers along a uniaxial direction, we achieved uniform sectional nanofibers of increasing gradient concentrations. Initial tests with SGNs show improved cell adhesion and decreased morbidity to microfabricated PLGA scaffolds. Our solid gradient nanofiber membrane is versatile, obviates the need for the complex microfluidic mixer system to generate an NT gradient, is potentially implantable, and can be used in other nerve regeneration studies in peripheral nerve system and central nerve system.

For over thirty years, the Hawaiian bobtail squid Euprymna scolopes has served as a model to understand the influences of beneficial bacteria on animal development and elucidate the molecular mechanisms of specificity during the establishment and maintenance of environmentally transmitted symbioses. The host has two symbiotic organs: the light organ (LO), which harbors a monoculture of bioluminescent Vibrio fischeri used for camouflage; and the accessory nidamental gland (ANG), a reproductive organ containing a bacterial consortium made up primarily of members of the Alphaproteobacteria and Verrucomicrobia that are thought to be used for egg defense. Our recent findings suggest that the LO and ANG originated by different evolutionary mechanisms yet how the host systemically regulates these associations is poorly understood. The bobtail squid offers a model system where one can study the mechanisms that govern both binary and consortial symbioses in the same host.

Although numerous tools have been developed for the symbiont V. fischeri, there have been significant challenges associated with building effective tools for its host. For example, studying individual host cell responses during different developmental stages have been limited. Gene expression studies have typically been conducted on whole organs that contain many different cell types. By developing nanomagnetic tools to study direct interactions between the symbionts and host cells, we will likely better resolve the molecular conversations that occur between the partners and uncover evolutionary conserved mechanisms by which aquatic hosts and environmentally transmitted bacteria form associations. The development of novel tools for the genetic manipulation and capture of targeted host cells coupled with the short developmental cycle and ease of maintaining the animals in the lab will hasten insights into the genetic basis of phenotypes in aquatic symbioses.

The goals for this project are to: 1) enable the capture of several key cell types within the host symbiotic tissues using magnetic nanoparticle technology; 2) conduct targeted mRNA, protein and metabolomic analyses on the captured cell populations to identify potential heterogeneity of host responses; 3) develop transgenic host hemocytes to manipulate immune responses in the system and 4) develop magnetofluorescent nanoparticles for in vitro and in vivo regulation of receptors on epithelial cells associated with the host symbioses. These technological advances coupled with the recently sequenced genome of the host animal will provide a critical foundation to explore the genetic architecture and toolkits animals need to form symbioses with microbes.

We are developing ultra-compact antennas, where the antenna size is much smaller than the electromagnetic wavelength.

Pervasive wireless connectivity is a must for today’s interconnected world. Many MHz-GHz communication systems require antennas with physical sizes that can be much larger than the entire size of the system. It is difficult to achieve good antenna performance if the size of the antenna is less than 1/10ththe electromagnetic wavelength (e.g. minimum of 3 cm at 1 GHz)

Our breakthrough approach is radically different than traditional conductive-wire type antennas. Rather than relying on moving charge to enact antenna functionality, we make use of functional materials. Specifically magnetoelectric composite nanowires (strain-coupled piezoelectric + magnetostrictive materials) respond to an electromagnetic field by directly producing a voltage. This is material effect, rather than a purely electromagnetic effect. Additionally, the antenna performance can be dramatically enhanced by tuning the mechanical/acoustic resonance of the device to the target frequency band. The ability to make ultra-compact antennas, and potentially on-chip with integrated electronics could drastically reduce the size, weight, and power (SWAP) of multi-functional systems.

Chemical and Biomedical Systems

The Electrospinning and Stamp-thru-mold (ESTM) technique, an integrated fabrication process which incorporates the versatility of the electrospinning process for nanofiber fabrication with

the non-lithographic patterning ability of the stamp-thru-mold process is introduced. In-situ multilayer stacking of orthogonally aligned nanofibers, ultimately resulting in a nanoporous membrane, has been demonstrated using orthogonally placed collector electrode pairs and an alternating bias scheme. The pore size of the nanoporousmembrane can be controlled by the number of layers and the deposition time of each layer. Non-lithographic patterning of the fabricated nanoporousmembrane is then performed by mechanical shearing using a pair of pre-fabricated micromolds. This patterning process is contamination free compared to other photo lithographical patterning approaches. The ability to pattern on different substrates has been tested with and without oxygen plasma surface treatment. In vitro tests of ESTM poly-lactic-coglycolic acid (PLGA) nanofibers verify the biocompatibility of this process. Simulation by the COMSOL Multiphysics tool has been conducted for the analysis of electrospun nanofiber alignment.

The goal of this project is to develop a miniature two-photon microscopy probe with light weight and use it on freely behaving mice for in vivo 3D neural imaging. Both 2-axis MEMS scanning mirror and z-axis tunable microlens will be developed. Double-cladding photonic crystal fibers will be used to accommodate the excitation laser and the frequency-doubled two-photon signals.

The goal of this project is to develop an OCT system with a miniature imaging probe that can utilize birefringence for enhanced contrast as well as provide vascular distribution information.

Chronic and acute pain affect ~100 million people in the US and greatly increase national rates of morbidity, mortality, and disability. Pain not only negatively impacts individual lives in significant ways, it also imposes enormous national economic costs (up to $635B annually). The misuse of and addiction to opioids, such as prescription pain relievers, heroin, and synthetic opioids (e.g., fentanyl and carfentanil) is a serious national crisis. Currently ~130 Americans die of opioid overdose every day. Although pain treatment is a significant factor of the opioid crisis, it is not the only one. For example, despite a 13% reduction in opioid prescriptions from 2012 to 2015, the addiction to opioids actually drove the overdose death rate up 38%. Opioid addiction can also be driven by causes other than pain, such as social, economic, and "diseases of despair". By tackling this national crisis, the proposed center-planning effort will align with a major priority of the United States (i.e., The President’s Commission on Combating Drug Addiction and the Opioid Crisis) and the states of Florida, Pennsylvania, and Arizona which in 2017 had the 3rd, 4th, and 22nd most opioid-overdose deaths in the country respectively. Inspired by the neurotechnological breakthroughs enabled by the convergence of engineering with the fields of neuroscience, neurology, and neurosurgery (e.g., cochlear implants, deep-brain stimulation, retinal prosthetics, etc.), our vision is to achieve lasting transformative impact on the opioid crisis with new neural-engineered systems that can dramatically reduce pain and others that reduce addiction. To plan the Center for Neural Engineering Systems with Societal Impact (NESSI), we propose to build a large coordinated team that leverages new social and neuroscientific insights, computational modeling techniques, artificial intelligence, advanced engineering fabrication processes, preclinical experimental methods, and translational strategies to tackle this increasingly global societal challenge. Overview: Our proposed ERC-planning process will include training to ensure it is informed by the best practices of inclusion and unconscious bias. Also, a set of working-group (WG) meetings will focus on 5 primary research themes: Target, Model, Implement, Validate, and Translate. Output from earlier WG meetings, such as reports and SWOT analyses, will be passed on to later WG meetings to inform their discussion. The outputs of all WG meetings will be considered at an Integration Meeting focused on bringing all of the guidance together and developing preliminary vision documents for the research, workforce-development, inclusion, and innovation-ecosystem components of the center. Lastly, a center-wide Final Strategic Meeting will be organized to solidify the center vision for all components.

Chronic and acute pain affect ~100 million people in the US and greatly increase national rates of morbidity, mortality, and disability. Pain not only negatively impacts individual lives in significant ways, it also imposes enormous national economic costs (up to $635B annually). The misuse of and addiction to opioids, such as prescription pain relievers, heroin, and synthetic opioids (e.g., fentanyl and carfentanil) is a serious national crisis. Currently ~130 Americans die of opioid overdose every day. Although pain treatment is a significant factor of the opioid crisis, it is not the only one. For example, despite a 13% reduction in opioid prescriptions from 2012 to 2015, the addiction to opioids actually drove the overdose death rate up 38%. Opioid addiction can also be driven by causes other than pain, such as social, economic, and "diseases of despair". By tackling this national crisis, the proposed center-planning effort will align with a major priority of the United States (i.e., The President’s Commission on Combating Drug Addiction and the Opioid Crisis) and the states of Florida, Pennsylvania, and Arizona which in 2017 had the 3rd, 4th, and 22nd most opioid-overdose deaths in the country respectively. Inspired by the neurotechnological breakthroughs enabled by the convergence of engineering with the fields of neuroscience, neurology, and neurosurgery (e.g., cochlear implants, deep-brain stimulation, retinal prosthetics, etc.), our vision is to achieve lasting transformative impact on the opioid crisis with new neural-engineered systems that can dramatically reduce pain and others that reduce addiction. To plan the Center for Neural Engineering Systems with Societal Impact (NESSI), we propose to build a large coordinated team that leverages new social and neuroscientific insights, computational modeling techniques, artificial intelligence, advanced engineering fabrication processes, preclinical experimental methods, and translational strategies to tackle this increasingly global societal challenge. Overview: Our proposed ERC-planning process will include training to ensure it is informed by the best practices of inclusion and unconscious bias. Also, a set of working-group (WG) meetings will focus on 5 primary research themes: Target, Model, Implement, Validate, and Translate. Output from earlier WG meetings, such as reports and SWOT analyses, will be passed on to later WG meetings to inform their discussion. The outputs of all WG meetings will be considered at an Integration Meeting focused on bringing all of the guidance together and developing preliminary vision documents for the research, workforce-development, inclusion, and innovation-ecosystem components of the center. Lastly, a center-wide Final Strategic Meeting will be organized to solidify the center vision for all components.

The aim of this project is to utilize the controllable nature of Graphene Oxide as an ultrathin separation membrane in biological applications, specifically targetting removal of uremic toxins.

For patients to benefit from state-of-the-art high-channel-count neural-interface technology, translatable implant packaging technology is needed to support it. Despite advances in implant electronics, batteries, enclosures, and even high-feedthrough-count and high-feedthrough-density headers, the lack of advancement in implant connector technology has imposed an often-unacceptable tradeoff between high interface channel count and the ability to disconnect and reconnect implanted interface leads from packaged and implanted electronics. Specifically, it would be of great value to enable battery changes, implant electronics replacement, or implant electronics upgrades to be performed without disturbing high-channel-count thin-film interfaces that have become integrated into delicate and sensitive neural tissue. We propose to revolutionize implantable connector technology by creating miniature, reliable, and high-channel-density connectors for high-channel-count neural interfaces produced with thin-film microfabrication technology. To do this we will advance and miniaturize three critical connector components: (1) the gaskets used to reliably achieve and maintain high channel density and channel-to-channel isolation even without hermeticity; (2) the conductive spring elements in each via used to reliably achieve and maintain low-resistance contacts; and (3) a compact and easy-to-use mechanical mechanism to achieve and maintain a high-clamping force for sealing to the gasket and engaging the conductive springs between all contacts. In Specific Aim 1 we propose to develop and characterize the performance and reliability of a miniaturized thin-film implant-gasket technology so that higher channel densities are possible in implantable connectors without compromising channel-to-channel isolation. In Specific Aim 2 we propose to develop and characterize the performance and reliability of multi-point low-impedance electrical contacts between high-channel-density interface leads and high-feedthrough-density implant-packaging headers. To mitigate risk, we will explore three different approaches. First, we will pattern gaskets or fill gasket vias with a dense mixture of conductive metal particles and PDMS. Second, inspired by the mm-scale packaging technology called fuzz buttons, we will microfabricate fuzz buttons that consist of a dense mat of electrospun microfibers that can be patterned directly on top of the Pt vias in the ceramic header, pyrolyzed, and then coated with metal. Third, we will microfabricate multiple stress-engineered upward-curling microcantilever springs on top of each feedthrough of the ceramic-Pt substrate. Each approach is designed to achieve multiple points of contact for low impedance and a restoring spring force to maintain electrical connection spanning the gasket over time. In Specific Aim 3 we propose to develop and characterize the performance and reliability of the clamping mechanism needed to deliver enough force to achieve reliable channel-to-channel isolation and low contact impedance. For each aim we will use an aggressive reactive-accelerated-aging soak test that mimics a strong tissue response to challenge the reliability of each component of the advanced implantable connector.

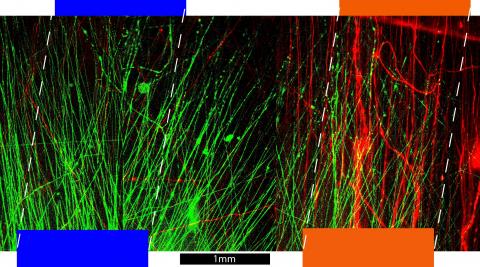

Spatially controlled electrospun solid gradient nanofibers for guided spiral ganglion neuron culture

The direction of cell growth is associated with chemical, structural and/or mechanical properties of the substrate. Structurally, electrospun nanofibers provide a suitable environment for cell attachment and proliferation due to their similar physical dimension to that of the extracellular matrix. Furthermore, by modulating the topographical features of nanofibers, which include fiber diameter and orientation, cell growth and its related functions can be modified. Here, we demonstrate a solid gradient scaffold for directional growth of spiral ganglion neurons (SGNs). Spatial nanofiber alignment is controlled using a custom directional electrospinning setup. The electric field to spatially control the confinement of nanofibers was simulated with COMSOL Multiphysics simulation tool and experimentally verified. To promote neurite outgrowth and impart directionality to SGN cells, a spatial gradient of neurotrophin (NT) is introduced. By sequentially electrospinning solutions of increasing concentrations of NT in the biodegradable polymer and collecting sections of these aligned fibers along a uniaxial direction, we achieved uniform sectional nanofibers of increasing gradient concentrations. Initial tests with SGNs show improved cell adhesion and decreased morbidity to microfabricated PLGA scaffolds. Our solid gradient nanofiber membrane is versatile, obviates the need for the complex microfluidic mixer system to generate an NT gradient, is potentially implantable, and can be used in other nerve regeneration studies in peripheral nerve system and central nerve system.

For amputees to exploit the full capability of state-of-the-art prosthetic limbs with rapid fine-movement control and high- resolution sensory percepts, a nerve-interface with a large number of reliable and independent channels of motor and sensory information is needed. The strongest signal sources in nerves are the nodes of Ranvier, which are essentially distributed randomly within a small 3-D volume. Thus, to comprehensively engage with the electrical activity of a nerve, a neural interface should interrogate a nerve in a 3-D volume of the same scale. To date, the clinical translatability, performance, and/or operational lifetime of all existing nerve-interfaces are either: limited to low channel counts and/or non-3-D electrode arrangements, capable of detecting single-unit activity at only very low signal amplitudes that are often swamped by noise, and/or trigger a foreign body response linked to diminished channel performance over time. Our paradigm-shifting approach for 3-D scalable nerve interfaces is to integrate a stack of multi-electrode thin-film polyimide- metal electrode arrays (“threads”) into tissue-engineered biodegradable extracellular-matrix-based hydrogel nerve scaffold. We call this new class of neural interface Tissue-Engineered Electronic Nerve Interfaces (TEENI). In preliminary studies we demonstrated that we can (1) microfabricate multi-electrode arrays that can survive high- temperature reactive-accelerated aging (RAA) soak tests through the use of amorphous silicon-carbide and titanium adhesion layers between the metal and polyimide layers, (2) form a 3-D array of electrodes by integrating a stack of polymer-metal multi-electrode arrays into an extracellular-matrix-based hydrogel scaffold wrapped with small-intestinal submucosa (SIS) to support the hydrogel, provide suturable ends for attachment to the nerve, and facilitate easy surgical handling and implantation without limiting the design of the electrode array or damaging it, (3) achieve robust regeneration of vasculature and neural fibers into the TEENI scaffold, and (4) obtain chronic recordings of single-unit activity inside TEENI implants. However, we made two observations that motivated the specific aims for this proposal. First, we observed a tight tissue response around each thread that that could limit the density of 3-D TEENI multi- electrode-thread integration. Second, we observed that only a fraction of the regenerated nerve tissue preferentially grew along the microfabricated multi-electrode arrays, with the remainder growing along the inner surface of the SIS wrap and with incompletely degraded hydrogel between the two. In Specific Aim 1 we propose to reduce the size of the foreign body response in the same manner it has been achieved with microfabricated probes implanted into brain tissue: reduce the width and thickness of the implant to ~10 µm and ~1 µm respectively. In Specific Aim 2 we propose to use microchannel-templated hydrogels to increase the number and uniformity of axons and Schwann cells regenerating near the TEENI microfabricated multi-electrode arrays. To gain unique insight into the performance of TEENIs, we will visualize the 3-D distribution of electrodes, nodes, axons, vasculature, and any tissue response around the interface inside the regenerated nerve by employing device-capture histology, CLARITY, and light sheet microscopy.

A Tissue Engineered Electronic Nerve Interface (TEENI) combines research areas including flexbile MEMS device fabrication, Hydrogels, Magnetic Microparticle Templating, Tissue Scaffolding, and Nerve Regeneration to develop a highly compliant and versatile interface for stimulating and recording the peripheral nerve with the potential for electrode density to scale in a truly 3-Dimensionsal fashion.

Power and Energy Systems

As predicted by Moore's "law", the past few decades have seen massive reductions in the size of integrated circuits, enabling the portable, handheld devices now in everyday use. However, the components that power these devices have not experienced a similar size reduction. For example, the power adapter of a laptop computer is only modestly smaller than that two decades ago, and the printed circuit board inside a smart phone must dedicate between 20% and 40% of the board area for power conversion and management. To date, efforts towards miniaturization have been limited by both materials and manufacturing challenges. To address this gap, this research will study nanomanufacturing processes to facilitate the scalable synthesis of high quality magnetic nanoparticles and nanocomposite core materials and the fabrication of compact power inductors and transformers through assembly of these nanomaterials in a manner that is compatible with current manufacturing processes, such as silicon wafer or printed circuit board fabrication. This compatibility will enable fully integrated and compact system-on-chip or system-in-package power solutions. This research will be accomplished by fostering collaboration among disciplines including materials science, chemical engineering and electrical engineering. It will foster diversity in the profession by involving high school and undergraduate students in research activities and by broadening participation through the inclusion and engagement of women and underrepresented groups.

The overarching goal of this Scalable Nanomanufacutring project is to study synthetic and nanomanufacturing processes that overcome existing integration challenges while affording breakthrough, high-frequency magnetic performance. An aim is to research materials that exhibit high magnetic saturation and low loss. This will be accomplished by leveraging the unique properties of magnetic materials at the nanoscale through a combination of nanomanufacturing approaches spanning bottom-up synthesis to directed assembly and nanocomposite formation. The specific objectives are to: (i) scale-up synthesis of high quality magnetic nanoparticles via thermal decomposition routes by elucidating the underlying correlations between synthesis parameters and nanoparticle properties, leveraging recent developments in the reproducible synthesis of near defect-free nanocrystals with magnetic properties approaching those of the bulk; (ii) study methods for large-scale directed assembly of magnetic nanoparticles via dielectrophoresis into compact power inductors/transformers; and (iii) demonstrate the formation of bi-phasic nanocomposite cores through large-scale electro-infiltration of an additional ferromagnetic material. An expected outcome of this project is to demonstrate scalability through the full-wafer batch-fabrication of microinductor devices using the developed methods on a silicon wafer. From a commercial standpoint, nanomanufacturing technologies providing process-integrable, high-performance magnetic components for power application have the potential to impact a nearly $12B/year market.