High Temperature Optical Sapphire Pressure Sensors for Harsh Environments

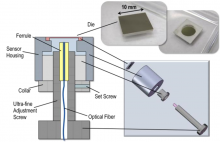

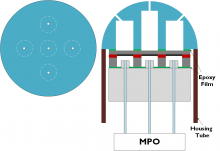

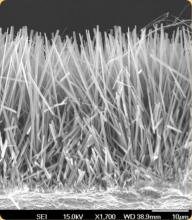

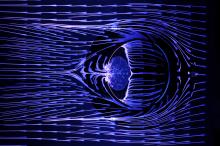

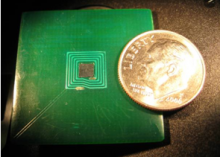

The primary objective of this research is to develop a high-bandwidth pressure sensor to provide benchmark, time-resolved, dynamic pressure data in high-temperature combustion environments. Specifically, these sensors will be designed to be embedded within a system and provide remote interrogation which will enable pressure to be measured in situ and on line under extreme conditions. Ultimately, this sensing technology will lead to better understanding and increased efficiency of complex power generation systems. In order to achieve this objective, research in sapphire laser micromachining and thermocompression bonding via spark plasma sintering technology will be conducted to enable fabrication of a fiber optic lever pressure sensor that uses a sapphire optical fiber for transduction of the pressure-induced diaphragm deflection. The proposed project will result in instrumentation-grade, high-temperature sensors that enable flush mounted measurements without sensor cooling. Furthermore, the use of optical techniques enables “passive” device operation, with electronics located remotely from the sensor. After fabrication and packaging, the pressure sensor will be rigorously characterized in acoustic plane wave tubes under both ambient and high-temperature conditions to determine its performance as a quantitative measurement device.

.png)