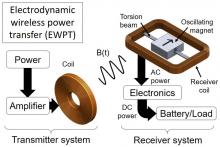

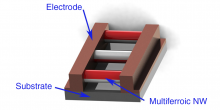

We seek to develop a platform that allows magnetic field sensing using a small footprint, in the absence of an external power supply. Our approach uses magnetoelectric nanofibers to create a zero-power magnetic field sensor. The challenge is to develop methods to assemble these materials into devices that leverage their unique anisotropic properties.

The figure of merit for magnetoelectric materials is the magnetoelectric coefficient, a measure of the amount of voltage generated with respect to the magnitude of the applied magnetic field. Bulk magnetoelectrics and thin films are limited by defects and substrate clamping respectively. To overcome the limitations of thin-film based composite magnetoelectrics we have developed magnetoelectric bilayer structures on a single nanofiber, i.e., 1D magnetoelectrics. These materials are theoretically predicted to have magnetoelectric coupling coefficients that are orders of magnitude greater than their thin film counterparts.

Magnetoelectric materials can be employed in a wide variety of applications including magnetic field sensors and tunable resonance energy harvesters. By optimizing for material system and architecture, drastic increases in magnitude of voltage generated with decreased size can be achieved. This could allow for more sensitive magnetic field sensors appropriate for a wider array of applications and decreased size to allow for easier integration into ICs.