The objective of the effort is to transition high-performance micromagnets into fully-integrated, batch-fabricated micromagnetic actuators for applications such as micro adaptive flow control.

Motivation

Magnetically-based electromechanical actuation schemes are ubiquitous in macroscale systems such as audio speakers, relays, solenoids, and electrical motors. However, implementation of these transduction schemes at the microscale is nearly nonexistent because of certain design and fabrication challenges—primarily the inability to integrate high-performance, permanent-magnet (magnetically-hard) films within more complex micromachined structures. As a result, most microfabricated transducers rely on other transduction mechanisms (e.g. electrostatic, piezoelectric, thermoelastic). However, these mechanisms limit the actuation force, stroke (displacement), power density, and efficiency necessary for certain applications.

The proposed actuator uses an adaptable and scalable actuation scheme, in that the device structure can be tailored for a wide range of applications. Examples include micro pumps/valves for microfluidic (gas or liquid) systems; high power density motors/actuators for microrobotics; or low-profile acoustic radiators for navigations/sensing. The evolution of fully-integrated micromagnetic transducers will enable performance improvements for existing applications and opportunities to explore new transformative technologies.

Objectives

(1) to validate and characterize the integrability (chemical stability, temperature stability, mechanical reliability, magnetization methods etc.) of the permanent magnet materials in complex microfabrication process flows

(2) to model and optimize a multi-magnet out-of-plane microactuation scheme

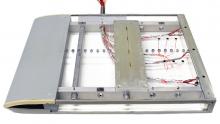

(3) to fabricate and characterize a fully-integrated out-of-plane piston-type actuator that can be directly implemented as a micro aerodynamic control surface or adapted as a synthetic jet actuator

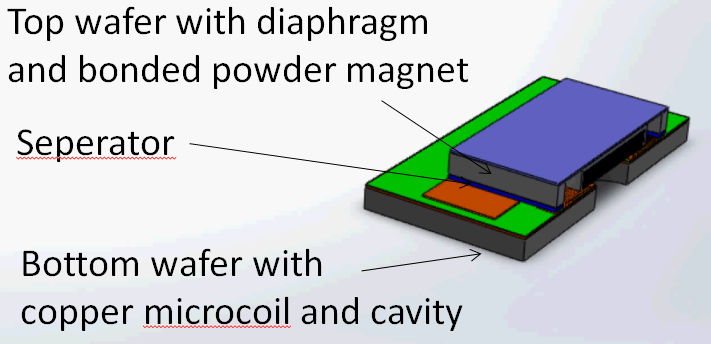

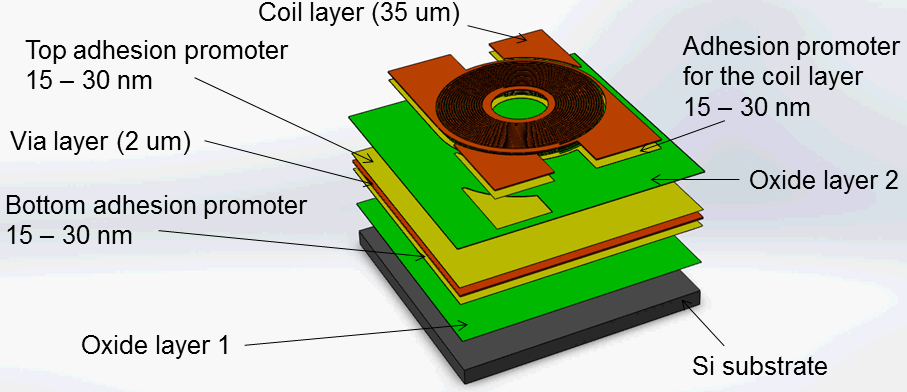

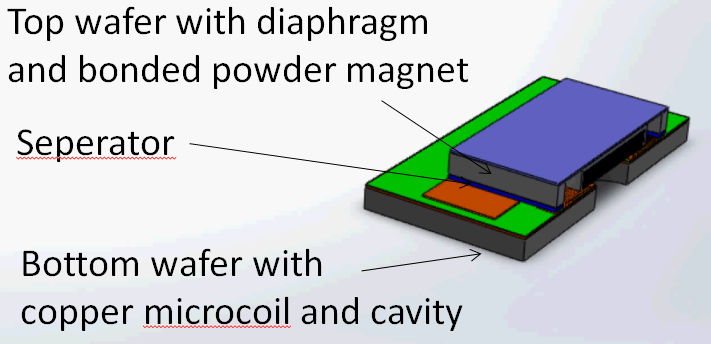

(a)

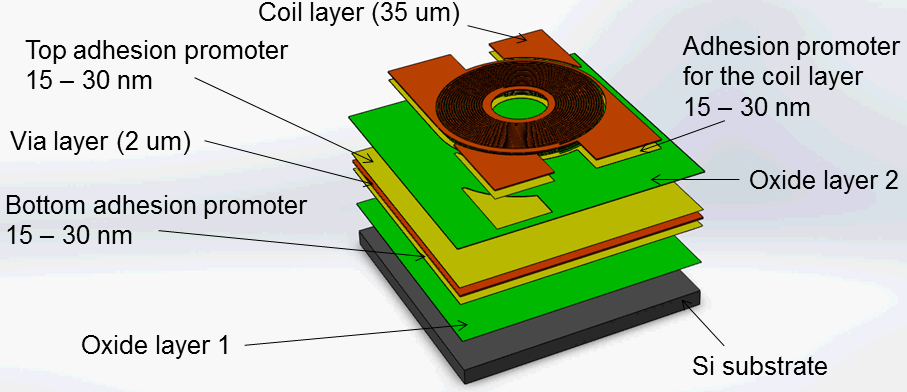

(b)

Figure 1: CAD drawings of the proposed micro-electrodynamic synthetic jet actuator actuator: (a) Actuator assembly comprising two dies made from silicon substrate, separated by a separator. The top die is covered with a PDMS diaphragm and has a bonded powder magnet in the center. (b) Exploded view of the bottom wafer.