Optical Shear Stress Sensor

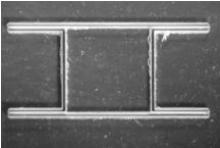

Design, fabricate, calibrate, and test time-resolved, direct shear stress sensors capable of measuring stresses in harsh environments using miniaturized optics. Optical gratings on the floating element sensor generate Moire fringe patterns for optical amplification of the floating element displacements due to applied shear stress.