NSF Engineering Research Center for the Internet of Things for Precision Agriculture (IoT4Ag)

See www.iot4ag.us for more information.

See www.iot4ag.us for more information.

As predicted by Moore's "law", the past few decades have seen massive reductions in the size of integrated circuits, enabling the portable, handheld devices now in everyday use. However, the components that power these devices have not experienced a similar size reduction. For example, the power adapter of a laptop computer is only modestly smaller than that two decades ago, and the printed circuit board inside a smart phone must dedicate between 20% and 40% of the board area for power conversion and management. To date, efforts towards miniaturization have been limited by both materials and manufacturing challenges. To address this gap, this research will study nanomanufacturing processes to facilitate the scalable synthesis of high quality magnetic nanoparticles and nanocomposite core materials and the fabrication of compact power inductors and transformers through assembly of these nanomaterials in a manner that is compatible with current manufacturing processes, such as silicon wafer or printed circuit board fabrication. This compatibility will enable fully integrated and compact system-on-chip or system-in-package power solutions. This research will be accomplished by fostering collaboration among disciplines including materials science, chemical engineering and electrical engineering. It will foster diversity in the profession by involving high school and undergraduate students in research activities and by broadening participation through the inclusion and engagement of women and underrepresented groups.

Objectives

To develop electro-mechanical inductors coupling between a conventional inductor and a mechanical resonator that passively store energy via both electromagnetic and mechanical mechanisms.

Benefits

Enable high density inductive energy storage, and potentially lighter, more efficient power converters.

Concept

Model

Preliminary Results

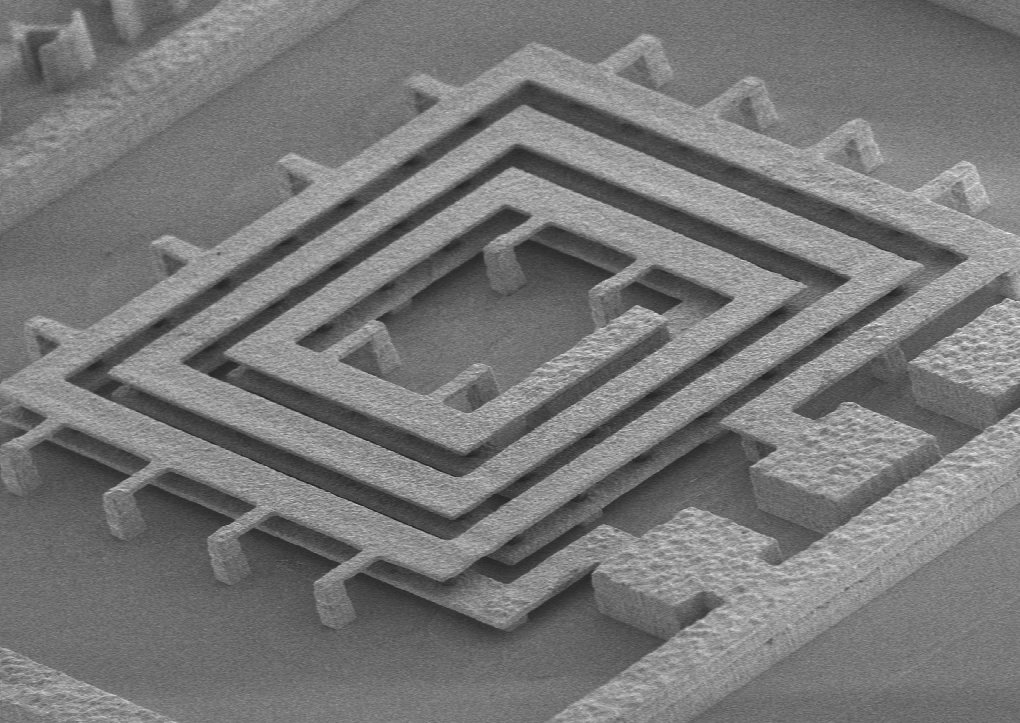

High density passive components (inductors, transformers, capacitors) are developed and integrated with high frequency (100-500 MHz) CMOS switching power conversion circuits. The mm3-scale integrated converter will be capable of delivering >20 V from a battery source to enable mobile microsystems such as micro air vehicles and microrobots.

High-inductance-density air core inductors and transformers have been fabricated using a three-dimensional copper electroforming process. These devices have measured inductance densities > 100 nH/mm2 and quality factors > 20. Optimal performance is achieved in the range of 50 MHz - 500 MHz to enable next generation switching converters operating at very high frequencies.