Ultra-High Energy Nanocomposite Capacitors

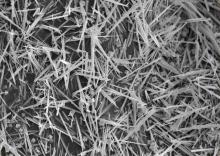

High energy density capacitors are critically important in advanced electronic devices and electric power systems that require bursts of large energy such as pace makers, defibulators, rail guns, electric vehicles and electromagnetic armor. Our work is studying the use of nanocomposites to create ultra high energy density capacitors with particular focus on the role the morphology and orientation of the filler plays on the energy density. Our current results have produced nanocomposites with energy density exceeding 10 J/cc, which is more than twice as large as high performance commercial materials. Efforts to create further gains are focused on the synthesis of new high dielectric ceramic nanowires, approaches for the functionalization of the fillers to achieve improve compatibility with the polymer matrix materials and fabrication approaches to create the highest energy density capacitors available.