Photoresponsive Polymers for Autonomous Structural Materials with Controlled Toughening and Healing

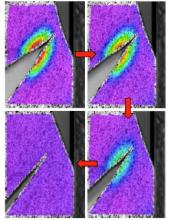

Our research goal is to develop photoresponsive shape memory polymers (SMPs) that incorporate cinnamic acid and cinnamylidene acetic acid which are able to undergo efficient photoreversible reactions when exposed to alternating wavelengths of light. The hope is that this reversible reaction will be used to actively cleave and reform covalent crosslinks to mitigate the propagation of damage though local fracture, achieve shape recovery for crack closure, and to ultimately reform crosslinks across the crack face to recover the strength of the original material. Our current results have shown that we can produce 1200% increased toughness, recover the plastic deformation of the specimen following loading to return it back to its original dimensions and subsequently achieve 96% healing efficiency without the reformation of crosslinks in the polymer. This work was featured live on CNN and various other news outlets.

This approach is novel in that using adaptation of the local stiffness to mitigate the propagation of damage followed by healing has not been studied in the literature; therefore this work has the potential to make significant advances in the design of autonomous structures and in the development of greater post-treatment measures concerning fractured areas. The effort from this research will ultimately provide methods to create materials that function and respond to damage; mimicking what some biological systems naturally do.

.png)