Levitated Microfactories for High-speed Adaptive Microassembly

The overall goal of UF’s effort on this DARPA Atoms to Products program (under sub-contract to SRI International) is to manufacture the micro-robots for demonstration of a massively parallel (1,000+) micro-robot factory. Each micro-robot comprises at least one magnetic base and one end effector. The magnetic base is configured with a pattern of north and south poles. A starting design is a 3 mm x 3 mm x 0.4 mm thick base that is arranged into a 9-pole checkerboard pattern. The simplest end effector is a simple mechanical rod attached to the top of the magnetic case.

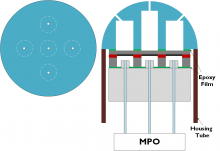

The micro-robot platforms (magnetic bases and end effectors) will be mass manufactured using a combination of precision manufacturing and microfabrication techniques. Rather than assembling discrete magnets into specific pole patterns, selective magnetization techniques will be used to “imprint” the desired pole pattern into mechanically contiguous layers. These methods will eliminate the need for assembly, and also facilitate the massive batch manufacture of many magnetic bases in parallel. Concurrently, end effectors will be microfabricated using suitable microfabrication technologies. The bases and end effectors will be combined together via monolithic co-fabrication or via wafer-scale batch-assembly processes.