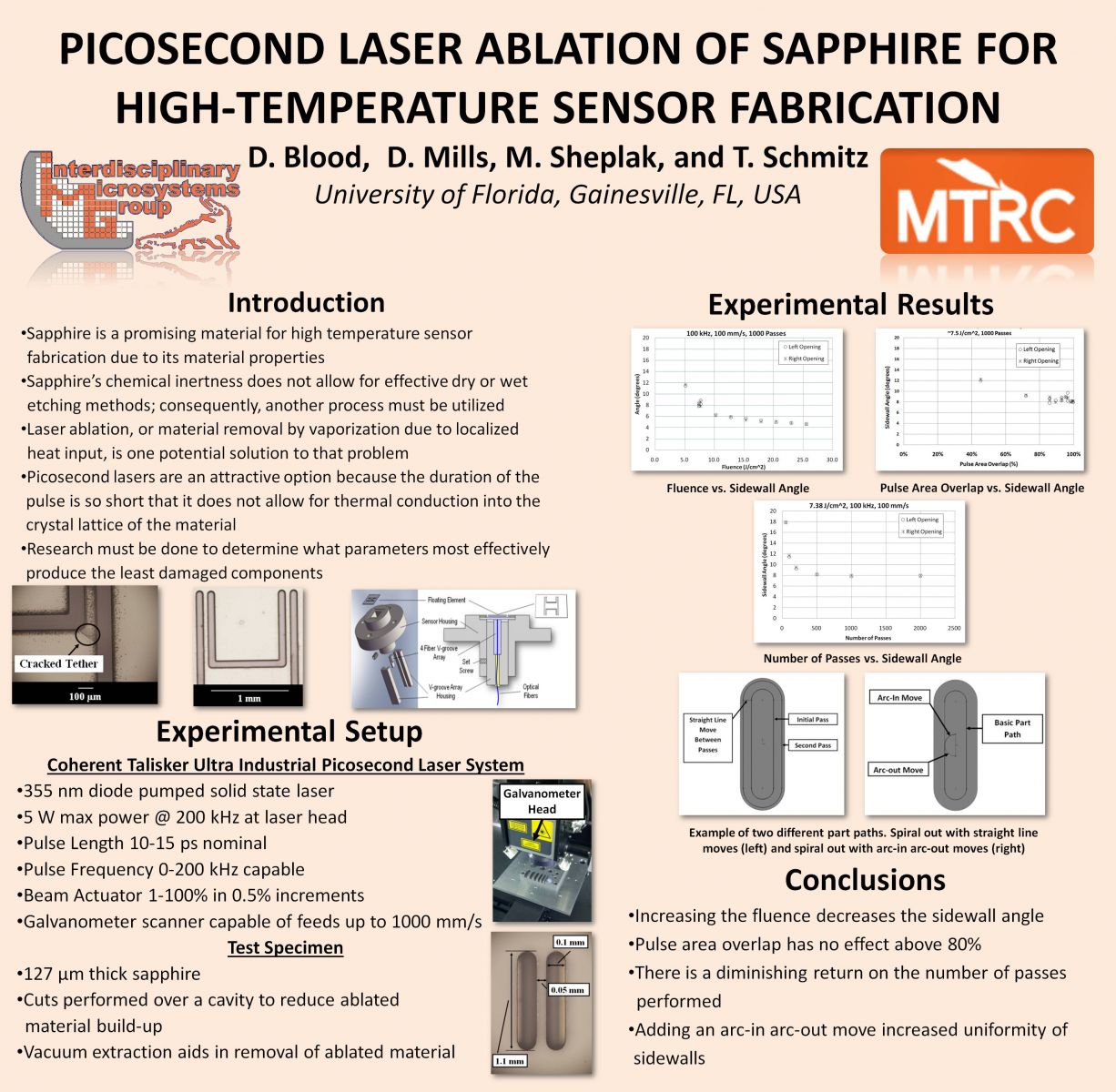

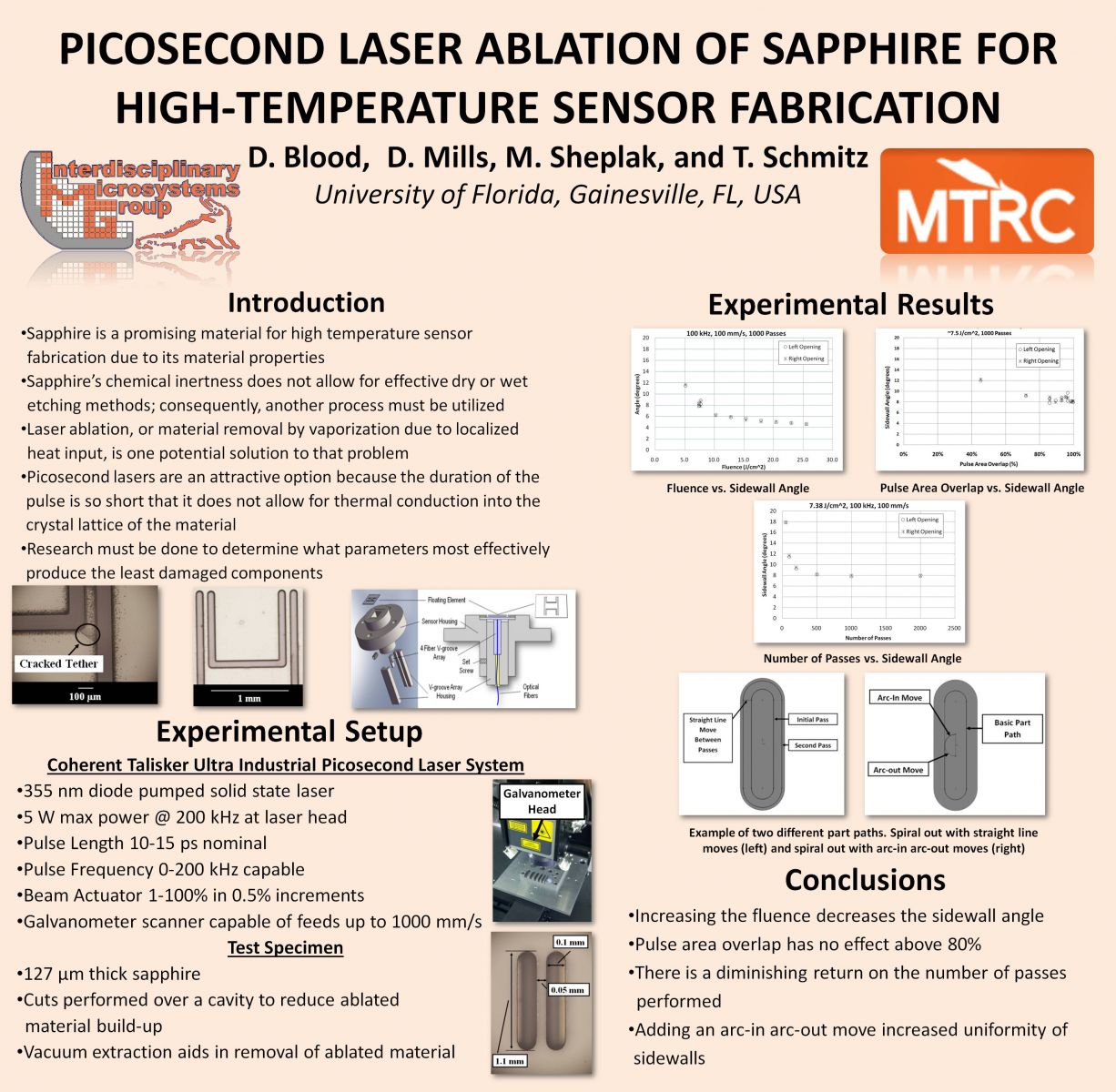

As engineers seek to design more efficient gas turbines, they require a detailed understanding of fundamental thermal-fluid phenomena, as well as active control methods, in high-temperature environments. The high-temperature requirement is based on the increasing turbine inlet temperatures, which have risen to 1500 C, in combined cycle systems in order to improve turbine peak power and efficiency. The limited survivability of silicon-based MEMS sensors in high-temperature and harsh environments has caused researchers to investigate other materials for high-temperature MEMS-based sensors; more specifically sapphire.

Sapphire’s material properties make its entry into the world of high temperature sensors promising, but it also renders most traditional MEMS manufacturing methods impractical. Sapphire’s chemical inertness does not allow for effective dry or wet etching; consequently, a more effective method of machining the material is necessary. One potential solution is to use laser ablation, or material removal by vaporization due to localized heat input, to pattern the material. Femtosecond and picosecond pulsed lasers have shown the ability to reduce or eliminate the thermal damage issues of longer pulsed lasers. These lasers are classified as ultrashort pulse width because the duration of the pulse is so short that it does not allow for thermal conduction into the crystal lattice of the material.